Our superior product performance comes from our high quality wear-reisistant rubber

Why is Xinhai rubber wear-resistant?

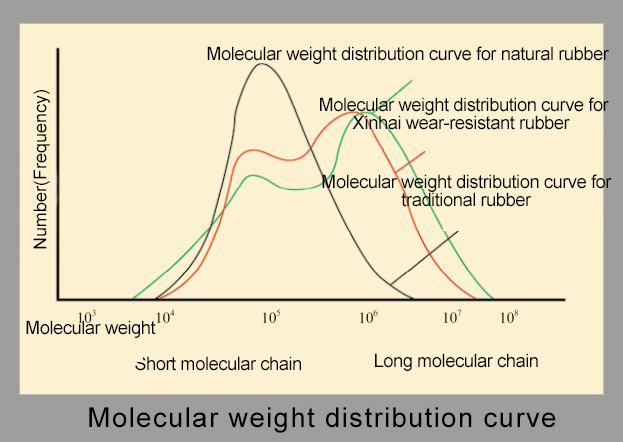

Tips:The wear-resistance of rubber products depends on the pure rubber and molecular chain length. Therefore, the wear-resistance can be strengthened by keeping high content of the pure rubber and reducing the damage of molecular chain.

After continuous exploration and research, Xinhai rubber company has successfully developed "Liquid phase nanometer compounding·normal temperature high-frequency curing" wet rubber processing technology, and has broken more than 80 year's monoply in rubber field. The performance index of Xinhai rubber products has achieved the international advanced level especially in the wet slurry conditions. Its wear-resistant index, tear strength and resilience are second to none, so it has become the real "wear-resistant rubber king" !

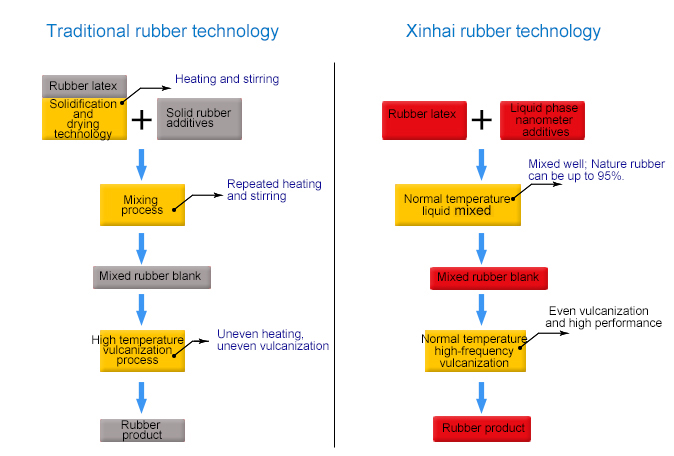

| Traditional rubber technology | Xinhai wet processing technology | |

|---|---|---|

| Rubber Blank |

Multiple heating treatment, greatly reduced the rubber performance Continous powerful agitation, the long molecular is destroyed and strong resilience is reduced solid additive and solid rubber block mix unsufficiently, and the rubber product performance may be imbalanced. large amount of additives lowers the nature rubber s.p. |

Unique liquid phase nanometer additives and nature rubber mixed well in normal temperature, which avoids solidification and drying and keeps the excellent performance |

| Valcanization |

High temperature sulfuration, uneven internal and external heating, the state of vulcanization of rubber may be different, and the product performance may be imbalanced. | Normal temperature high-frequency curing, heat well in internal and external, stable product performance |

Three advantages of Xinhai wear-resistant rubber

Real wet processing technology, the guarantee of rubber properties.

In traditional rubber productive technology, nature latex is purified, solidified, dewatered, washed, prilled, dried, classified and packaged after collected from the rubber trees and becomes solid natural rubber. In order to shorten the drying time, rubber latex should be crushed and prilled after dewatering, thus the polymer chains will be damaged by shearing force.

Xinhai adopts normal temperature and liquid phase mixing process to produce rubber, thus the polymer chains will not be damaged and keep the outstanding inherent properties.

From all kinds of molecular weight distribultion curves we can see:in troditional rubber, the long molecular chains are largely destroyed; long molecular chain content is very low;there are a lot of broken chains. And the molecular chain of Xinhai wear-resistant rubber is close to nature rubber, it maximumly keeps the wear-resistant properties of nature rubber.

Patented nanometer additives, high grade rubber security

In general, traditional rubber has the following problems: It is difficult to maintain the natural rubber polymer chain and uniform mixing at the same time. For this reason, Xinhai discovered excellent powder auxiliary agent, which mixes with nature rubber at normal temperature.

Xinhai rubber additives adopt advanced nanometer reinforcing technology, with surface treatment of nano material, which makes the combination between natural latex and auxiliary agent more firm and uniform. Besides, mixed with natural rubber latex in the liquid environment, not only can be uniformly mixed and require fewer doses, and can guarantee high content of natural rubber.

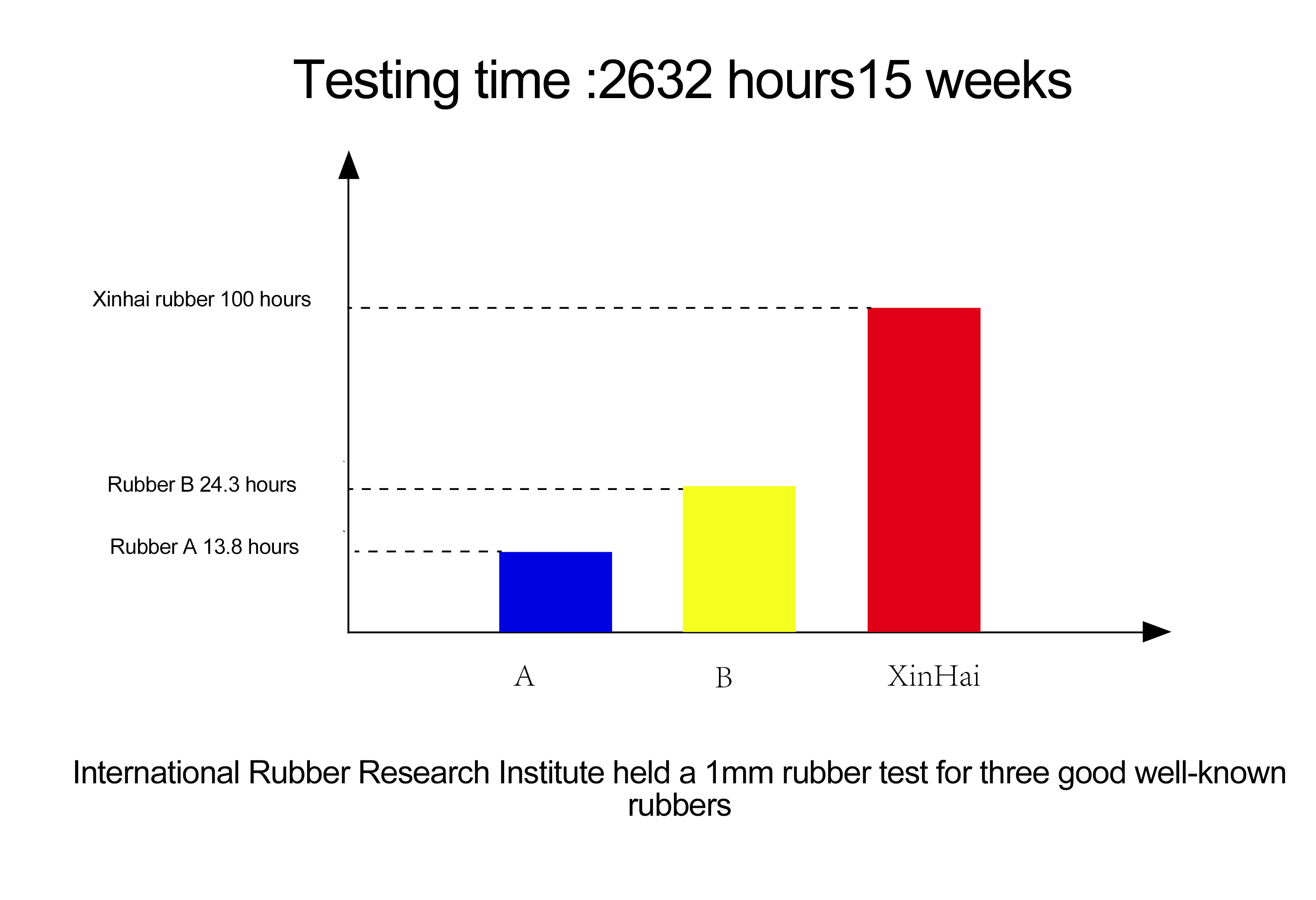

With nano coagulator, they can be instantaneously solidified into the rubber in normal temperature, completely eliminate the traditional heating process and guarantee the integrity of rubber polymer chains. It has been clearly proved by the wear test that the wear-resisting property of Xinhai rubber far exceeds the other rubbers.

Xinhai wear-resistant rubber rubber tape of 0.25mm stretched to 800%!

Resilience of Xinhai wear-resistant rubber reaches 80%!

Tensile strength of Xinhai wear-resistant rubber reaches 26.6MP!

Normal temperature high-frequency vulcanization, superior performance security

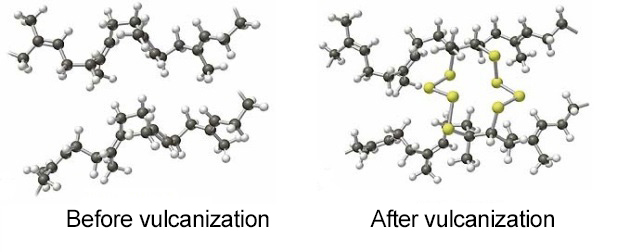

Vulcanization: Adding the curing agent to semi-finished rubber products, the rubber linear molecular interconnected into a three-dimensional network structure by generating "sulfur bridge", so as to increase the elasticity of the rubber.

Traditional process can't ensure even heating, especially for large size products,

far more external heating than the internal heating,which results in “over cure” of external rubber,

and “under cure” of internal rubber. Uneven vulcanization seriously affects the overall performance of rubber products.

Xinhai normal temperature high-frequency curing,adopts high frequency induction heating, which makes the rubber heated evenly

and vulcanized at the same time.It not only reduces the vulcanization time, but also improves the quality

more even and with excellent overall performance.

Rubber test data

Rubber types |

Xinhai XH35 rubber |

National standard rubber |

International brand rubber |

|

|---|---|---|---|---|

Color |

Red, Yellow |

Black |

Red |

|

Performance parameter |

Testing standard |

Narure |

Nature |

Nature |

Hardness shore A |

GB/T 6031-1998 |

35 |

65 |

38 |

Tensile strenth Mpa |

GB/T 528-1998 |

22 |

26.52 |

23.3 |

Elongation at bresk% |

GB/T 6031-1998 |

866 |

426.8 |

728 |

Tension set% |

GB/T 528-1998 |

4 |

28 |

8 |

Tearing strength N/mm |

GB/T 529-1998 |

81.34 |

164.32 |

70.44 |

Resilience% |

GB/T 1681-1991 |

74 |

45 |

74 |

Specific gravity g/cm3 |

|

0.95 |

1.1272 |

0.97 |

Wear-resistance index% |

GB/T 9867-1988 |

219 |

10.8 |

100 |

Wear-resistant products

Wear-resistant rubber“intimate”,product equipent“perfect”

With years of mining experience, Xinhai Group has perfectly "married" the wear-resistant rubber and beneficiation equipment, and developed a large amount of high efficiency products.

According to the real applications, Xinhai chooses wear-resistant rubbers with different functions for you, featured by durability and high efficiency. Many practices have proven that Xinhai wear-resistant equipment can not only improve the production, but also greatly reduce the running cost!

Patented wear-resistant product

Wear – resistant Slurry Pump

All lined with wear-resistant rubber, idealized pump for conveying erosion materials

Y-ball valve

Patented product, no block, a little valve saves a pipe for you

Hydrocyclone

Stable, high efficient and durable, one set does better than three sets