Ruber lined steel tube

- lined with Xinhai wear-resistant rubber, its service life is ten times longer than bare steel

- Unique techonology of cold bonding, rubber and steel tightly bonded without gap.

- Wear-resistant index over 128, corrosion resistance

- Flexible dummy club, flange connection 100% seal

0086 13810327080

Product features

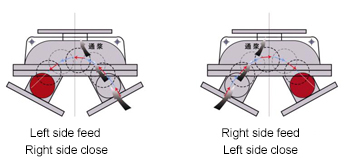

Unique ball valve design, Valve plug is almost zero

Unique ball valve design, flowing pulp drives the ball from one side to the other side and close it. When one side is opened, no slurry passes through the other side with no blockage problems.

With wear-resistant rubber valve lining, the valve life can be 2-4 times longer

The upper body and lower body of three-way auromatic change valve all lined with wear-resistant rubber, wear-resisitant index ≥128%,service lige is 2-4 times longer than traditional valve.

Greatly reduced the maintenance cost of the Y-ball valve.

Rubber ball valve, good seal, no leakage

The rubber ball has skeleton inside and vulcanizing outside with a layer of rubber

Moreover, wear-resistant rubber has good elasticity with resilience ≥76% and barely leakage in the real application

- Convenient automation control, more flexible in using

- A valve design, get rid of the disadvantages of slurry configuration that one for production, one for backup

- No need to manually operate the valve

- Complete the valve changing by the slurry pressure

- Automatic control makes it more convinient and simple

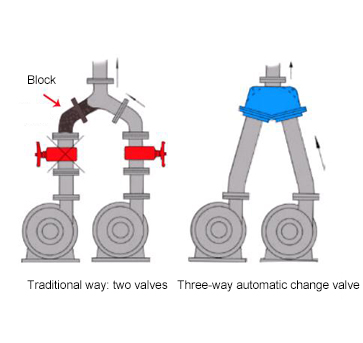

Y-ball valve has low investment cost, and it saves the cost for one more pipe line

The pump configuration that one for use one for spare has serious block problems at the tee joint and tied up the production

For this reason, many mining companies adopt two pumps and two pipes, but the pipe cost is too high.

For this reason, many mining companies adopt two pumps and two pipes, but the pipe cost is too high.

However, a Y-ball valve can be adequate to the work perfectly, you just need one valve cost and cut down one pipe investment.

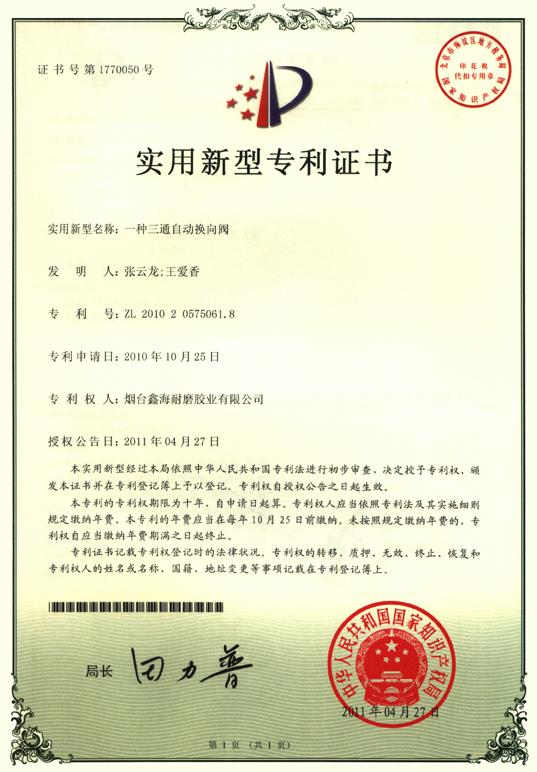

Xinhai Y-ball valve achieved the utility model patent certificate in 2010.

Patent No.:ZL 2010 2 0575061.8

FAQ

- Why is there an inner leakage phenomenon in the valve?

- Unsuitable length of valve rod makes the upper(or lower) distance not enough, and results in gap between valve core and valve seat. so it can not be fully engaged, which leads lax closing and leakage.

- How to solve this packing leakage problem?

- In order to make the feeding more convenient, we'd better feed at the top of the stuffing box, place a small metal protecting ring at the bottom of the stuffing box to prevent the medium erosion.

- The surface of stuffing box should be smooth, in order to reduce packing abrasion.

- Warm tips:

- Working pressure of Xinhai Y-ball valve:<=0.7Mpa

Product parameters

The conditions have great effect on the the revising valve selection, our technicians assit you to make the model selection Technical consultation

| Specs(DN) | A | B | C | Flange dimension | ||

|---|---|---|---|---|---|---|

| Center distance of bolt holes | Flange outer diameter | n-Φd | ||||

| 65 | 247 | 227 | 197 | 145 | 185 | 4-Φ18 |

| 80 | 267 | 250.5 | 217 | 160 | 200 | 8-Φ18 |

| 100 | 308.5 | 296 | 256.5 | 180 | 220 | 8-Φ18 |

| 125 | 352 | 346 | 300 | 210 | 250 | 8-Φ18 |

| 150 | 410 | 400 | 346.5 | 240 | 285 | 8-Φ22 |

| 200 | 477 | 476.5 | 413 | 295 | 340 | 8-Φ22 |

| 250 | 569 | 569 | 493 | 350 | 395 | 12-Φ22 |

| 300 | 656 | 669.5 | 580 | 400 | 445 | 12-Φ22 |

| 350 | 735 | 761 | 659 | 460 | 505 | 16-Φ22 |

| 400 | 833.5 | 863 | 747.5 | 515 | 565 | 12-Φ26 |

| 450 | 922.5 | 952 | 824.5 | 565 | 615 | 20-Φ26 |

| 500 | 1011 | 1054 | 913 | 620 | 670 | 20-Φ26 |

Just tell us your requirement and query, we will reply as soon as possible.

Note: the Name,Tel,E-mail,Country and is required

Wear-resistant products

-

Wear-resistant rubber sheet

-

Wear – resistant Slurry Pump

-

High Head Slurry Pump

-

Alloy slurry pump

-

Submerged Slurry Pumpp

-

Hydrocyclone

-

Dense medium cyclone

-

Y-ball valve

-

Pinch valve

-

Gate valve

-

Flexible check valve

-

High-efficiency multi-frequency dewatering screen

-

Wear-resistant rubber screen deck

-

Rubber Products