High-efficiency multi-frequency dewatering screen

- Patent for rear side dewatering design improves the dewatering speed by 30%

- Wear-resistant linings contributes to prolonging the service life for 10 times

- Strong double vibrating motors

- Enhance vibration force effect

- With a moisture of less than 10%

0086 13810327080

Product performance

- Rear side dewatering design improves the dewatering capacity

- Unique back side outlet design

- Most of the water outflows rapidly from this outlet

- Dewatering speed can be improved by 30%

- Avoid the motor damage caused by water

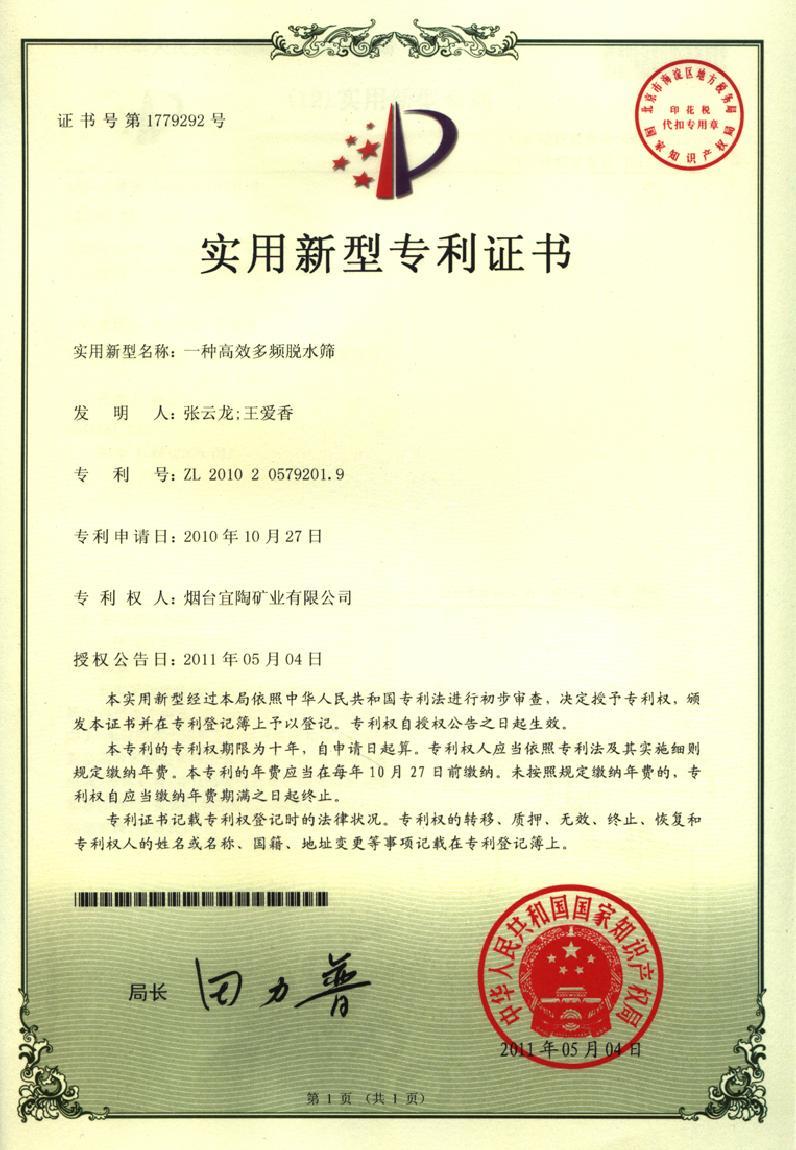

- It applied for a patent in Oct. 2010

- The assignment took effect in May 2011

- Patent No.:ZL 2010 2 057920.9

Outstanding wear-resistance; wear-resistant index over 128

Many internal parts are lined with Xinhai wear-resistant rubber with wear-resistant index over 128

Reduce iron contamination to the materials and comprehensively protect the dewatering screen from deformed due to fray

Moreover, Xinhai dewatering screen is fitted with snap-in modular screen deck panels made of wear-resistant polyurethane. Its service life is 10 times longer than wire screen deck

Avoid direct collision between screen metal framework and ore, reduce the noise, and reduce the massiness feelings of metal screen

Two vibrating exciter motors with compact and robust structure, increases the dewatering rate

The two parallel vibrating motors are installed horizontally and one is instaled on the top of the other

The rotation effect is caused by non-balancing gravity force.

Vibration effect is enhanced to make the screen operate stably and increase the dewatering capacity.

The moisture content can be finally reduced to 10% or lower

Product parameters

Application environment has great effect on the rubber seclon, our technicans assists you to make the selection. Get the details

| Model | Minimum feed slurry concentration 30% solids by volume(Improving the concentration if finer particles) | Unite motor power(KW) | ||||||

|---|---|---|---|---|---|---|---|---|

| Coal fines nominal -0.5+0.1mm SG 1.5 |

Concentrate sand aprox -5mm 100% -0.6mm50%,SG 2.7 |

Fine sand 90% -1mm SG 2.7 | 980rpm | 1460rpm | ||||

| 1460rpm | 980rpm | 1460rpm | 980rpm | 1460rpm | 980rpm | |||

| VD6 | 6-8 | 10-13 | 14 | 28 | 10 | 21 | 2.2 | 2.0 |

| VD9 | 9-12 | 15-20 | 21 | 42 | 16 | 32 | 3.0 | 2.2 |

| VD12 | 15-19 | 24-30 | 33 | 67 | 25 | 50 | 5.5 | 4.0 |

| VD12L | 18-24 | 28-35 | 40 | 80 | 30 | 60 | 5.5 | 4.0 |

| VD15 | 30-35 | 50-60 | 63 | 125 | 47 | 94 | 7.5 | 6.0 |

| VD18 | 35-45 | 60-80 | 77 | 153 | 57 | 115 | 7.5 | 6.0 |

| VD21 | - | 85-100 | - | 225 | - | 164 | - | - |

| VD24 | - | 95-110 | - | 250 | - | 190 | - | - |

Just tell us your requirement and query, we will reply as soon as possible.

Note: the Name,Tel,E-mail,Country and is required

Wear-resistant products

-

Wear-resistant rubber sheet

-

Wear – resistant Slurry Pump

-

High Head Slurry Pump

-

Alloy slurry pump

-

Submerged Slurry Pumpp

-

Hydrocyclone

-

Dense medium cyclone

-

Y-ball valve

-

Pinch valve

-

Gate valve

-

Flexible check valve

-

High-efficiency multi-frequency dewatering screen

-

Wear-resistant rubber screen deck

-

Rubber Products