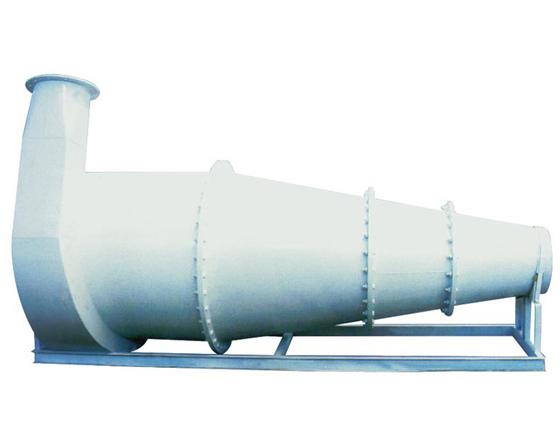

Dense medium cyclone

- Wide particle size range for good separating effects with high separating accuracy.

- Free and various for equipment arrangement

- A new feeding way, automatic control production

Xinhai provides four types of dense medium cyclones: XC3Y, XC2Y, XC3W, XC2W, so adapt to different beneficiation requirements of clean coal.Welcome consultations

0086 13810327080

Product performance

Upper limit of selected particles reaches 100mm, and lower limit reaches 0.5mm with good adaptability

Different specifications can meet the different needs of particle size, and the selected upper limit can reach 100mm, which greatly reduces the prepration before beneficiation and improves the capacity. At the same time, the strong internal centrifugal force is suitable for fine particles classification, and lower limit reaches 0.5mm.

With adjustable overflow pipe and underflow mouth diameter, it has high classification precision

When the dense medium cyclone works, suspension in the second stage comes from the concentrate of first stage, so the second stage separation density is not only related to the first stage separation density but also related to the Dia. of underflow outlet. Therefore, the separation density can be adjusted by changing the first stage overflow pipe and second stage underflow outlet in order to improve the classification precision.

Free and various for equipment arrangement to meet the different needs of customers.

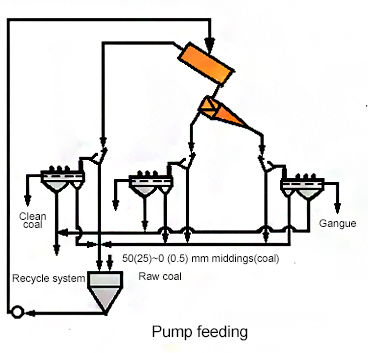

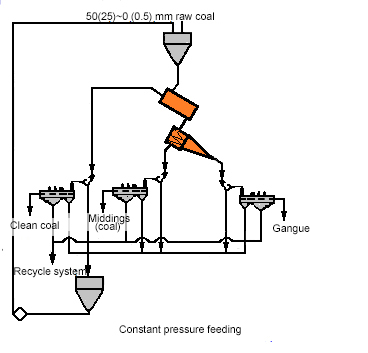

Xinhai dense medium cyclone can be horizontally or aslant placed. Meanwhile, it has two feeding ways: constant pressure feeding and pump feeding, which can meet the differnet production requirements. Pump feed can greatly reduce the plant height and simplify the working process to cut down the infrastructure investment. Constant pressure feeding makes light break for the clean coal and less abrasion to the pipe. It has no limit to the upper feeding, which reduces the medium circulation and makes the production more intuitive.

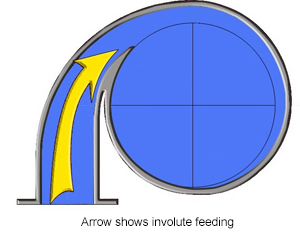

Involute feeding greatly reduce the abrasion.

When the dense medium cyclone works, fluid in the cyclone has a tangential velocity (>4.4m/s), serious wear of the parts.

In order to reduce the overcurrent abrasion, Xinhai dense medium adopts cyclone adopts involute feeding to improve the stability of fluid and classification effects.

Easy to achieve automation and improve the classification precision

The discharging of refuse and middings can be effectively controled by adjusting than chamber and discharge outlet of XC3W cyclone, it makes the production management more easier.

Besides, automatic control can be realized by using the cyclone automatic control system invented by Xinhai, which ensures the stable feeding and geatly improves the classification effect and separation precision.

Product parameters

Application environment has great effect on the rubber seclon, please let our technicans assists you to make the selection.Technical consultation

Xinhai can provide 4 types of dense medium cyclone to meet your needs, welcome to contact us!

| Specification & Dimension | Diameter(mm)First stage Second stage | Feeding particle size(mm) | Feeding pressure(Mpa) | Cpacity(t/h) | Mediun circulating load(m3/h) |

|---|---|---|---|---|---|

| XC3Y 500/350 | 500 350 | ≤20 | 0.06-0.10 | 35-60 | 180-250 |

| XC3Y 600/400 | 600 400 | ≤30 | 0.08-0.12 | 50-90 | 250-370 |

| XC3Y 710/500 | 710 500 | ≤35 | 0.09-0.14 | 90-130 | 370-540 |

| XC3Y 780/550 | 780 550 | ≤40 | 0.10-0.15 | 110-160 | 540-650 |

| XC3Y 850/600 | 850 600 | ≤45 | 0.13-0.16 | 120-180 | 650-700 |

| XC3Y 900/650 | 900 650 | ≤50 | 0.15-0.18 | 160-200 | 740-840 |

| XC3Y 1000/710 | 1000 710 | ≤55 | 0.18-0.22 | 200-250 | 840-1050 |

| XC3Y 1100/780 | 1100 780 | ≤60 | 0.20-0.24 | 240-280 | 1050-1250 |

| XC3Y 1200/850 | 1200 850 | ≤70 | 0.22-0.28 | 300-380 | 1250-1600 |

| XC3Y 1300/920 | 1300 920 | ≤80 | 0.26-0.32 | 350-450 | 1600-1900 |

| XC3Y 1400/1000 | 1400 1000 | ≤90 | 0.30-0.40 | 450-550 | 1900-2300 |

| Specification & Dimension | Diameter(mm)First stage Second stage | Feeding particle size(mm) | Feeding pressure(Mpa) | Capacity(t/h) | Medium circulating load(m3/h) |

|---|---|---|---|---|---|

| XC3W 500/350 | 500 350 | ≤20 | 0.05-0.08 | 35-50 | 140-180 |

| XC3W 600/400 | 600 400 | ≤30 | 0.06-0.10 | 50-80 | 180-300 |

| XC3W 710/500 | 710 500 | ≤35 | 0.08-0.12 | 80-120 | 300-420 |

| XC3W 780/550 | 780 550 | ≤40 | 0.09-0.13 | 100-150 | 420-540 |

| XC3W 850/600 | 850 600 | ≤45 | 0.10-0.14 | 120-180 | 480-620 |

| XC3W 900/650 | 900 650 | ≤50 | 0.12-0.16 | 140-200 | 560-700 |

| XC3W 1000/710 | 1000 710 | ≤55 | 0.15-0.18 | 180-230 | 700-800 |

| XC3W 1100/780 | 1100 780 | ≤60 | 0.18-0.22 | 220-280 | 800-1100 |

| XC3W 1200/850 | 1200 850 | ≤70 | 0.20-0.28 | 260-350 | 1100-1400 |

| XC3W 1300/920 | 1300 920 | ≤80 | 0.22-0.30 | 320-400 | 1400-1600 |

| XC3W 1400/1000 | 1400 1000 | ≤90 | 0.28-0.38 | 400-500 | 1600-2000 |

| XC3W 1500/1100 | 1500 1100 | ≤100 | 0.30-0.40 | 500-600 | 2000-2400 |

| Specification & Dimension | Diameter(mm)First stage Second stage | Feeding particle size(mm) | Feeding pressure(Mpa) | Capacity(t/h) | Medium circulating load(m3/h) |

|---|---|---|---|---|---|

| XC2W 350 | 350 | ≤15 | 0.04-0.06 | 25-35 | 80-130 |

| XC2W 500 | 500 | ≤30 | 0.05-0.08 | 35-60 | 130-180 |

| XC2W 600 | 600 | ≤35 | 0.06-0.09 | 60-80 | 180-260 |

| XC2W 710 | 710 | ≤40 | 0.07-0.10 | 80-110 | 260-320 |

| XC2W 800 | 800 | ≤45 | 0.08-0.12 | 110-150 | 320-440 |

| XC2W 900 | 900 | ≤50 | 0.10-0.16 | 150-180 | 440-540 |

| XC2W 1000 | 1000 | ≤55 | 0.15-0.18 | 180-220 | 540-650 |

| XC2W 1100 | 1100 | ≤60 | 0.16-0.22 | 220-250 | 650-800 |

| XC2W 1200 | 1200 | ≤70 | 0.20-0.25 | 250-320 | 800-1200 |

| Specification & Dimension | Diameter(mm)First stage Second stage | Feeding particle size(mm) | Feeding pressure(Mpa) | Capacity(t/h) | Medium circulating load(m3/h) |

|---|---|---|---|---|---|

| XC2Y 350 | 350 | ≤15 | 0.04-0.08 | 26-36 | 100-150 |

| XC2Y 500 | 500 | ≤30 | 0.05-0.10 | 36-60 | 120-180 |

| XC2Y 600 | 600 | ≤40 | 0.06-0.12 | 50-75 | 150-220 |

| XC2Y 710 | 710 | ≤50 | 0.08-0.12 | 70-140 | 210-400 |

| XC2Y 800 | 800 | ≤60 | 0.08-0.13 | 140-220 | 400-700 |

| XC2Y 850 | 850 | ≤60 | 0.09-0.13 | 220-280 | 700-880 |

| XC2Y 900 | 900 | ≤70 | 0.09-0.14 | 280-320 | 880-1050 |

| XC2Y 1000 | 1000 | ≤70 | 0.10-0.15 | 300-360 | 1050-1150 |

| XC2Y 1100 | 1150 | ≤80 | 0.10-0.16 | 350-420 | 1150-1300 |

| XC2Y 1200 | 1200 | ≤80 | 0.10-0.17 | 400-460 | 1300-1400 |

| XC2Y 1300 | 1300 | ≤90 | 0.10-0.18 | 460-540 | 1400-1600 |

| XC2Y 1450 | 1450 | ≤100 | 0.10-0.20 | 540-650 | 1600-2000 |

| XC2Y 1500 | 1500 | ≤100 | 0.10-0.20 | 650-740 | 2000-2300 |

Just tell us your requirement and query, we will reply as soon as possible.

Note: the Name,Tel,E-mail,Country and is required

Wear-resistant products

-

Wear-resistant rubber sheet

-

Wear – resistant Slurry Pump

-

High Head Slurry Pump

-

Alloy slurry pump

-

Submerged Slurry Pumpp

-

Hydrocyclone

-

Dense medium cyclone

-

Y-ball valve

-

Pinch valve

-

Gate valve

-

Flexible check valve

-

High-efficiency multi-frequency dewatering screen

-

Wear-resistant rubber screen deck

-

Rubber Products